TL series flue gas desulphurization pumps are single stage single suction centrifugal pumps,

which are applied for wet flue gas desulphurization equipment(FGD)in power plant,transmitting corrosive

slurry for absorption tower circulation pump.They are characterized by large capacity,high efficiency,

wear-resistance,compact structure,reliable running and low vibration,etc.The technical indexes reach

the same kind product level home and aboard .The most important advantages are their excellent performances and easy maintenance.

Application Area

The desulphurization pumps have been applied in limestone plaster wet desulphurization equipments.

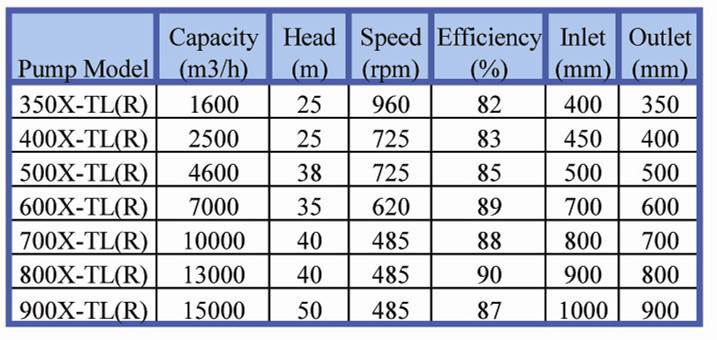

Performance Range

Outlet Diameter:----- 350-1000mm

Capacity:-------------- 1600-15000 m3/h

Head:------------------ 15-31m

Rotation Speed:------ 485-960 r/min

Power:----------------- 1.1-1250kw

Structural Characteristics

Flue gas desulphurization pump is single stage single suction centrifugal pump,which applies support structure.The material option has fully metal or natural rubber plus metal to meet different users’ requirements.

The pump has a better efficiency by using advanced hydraulic model and computational fluid dynamic software(CFD) to improve it.

End face seal is applied for impeller.Impellers can be optimally positioned by adjusting bearing assembly,which can enhance pump reliability and ensure that pump is highly efficient in operation.

Wet parts adopt different materials combination based on different work conditions to make pump manufacture and usage the most economic and reliable.

Pump can be disassembled form front and back,unnecessary to disassemble inlet and outlet pipelines,which is convenient for maintenance.

Thin oil lubrication is used on the bearings,which can improve the lubricating and cooling condition and also extend service life of bearings.

Seal can be selected according to different users and work conditions.There is assembly mechanical seal,packing seal,and auxiliary impeller with packing seal.In order to run reliably,wear-resistant corrosion-resistant metal rings are applied for seal rings in the case of assembly mechanical seal ,which can enhance seal ring capacities of anti-impact and heat dissipation and also can be washed down from inside or outside.

Platinum resistance is fitted on bearing for testing bearing temperature to avoid damage of bearing.