Overview

1. Applicable for conveying media such as sludge, ore slurry, coal slurry, sandstones containing big solid particles, pumping sand for building, silt sand, silt, tailing slurry, ore, iron sand ore, sediment in sewage treatment works, etc.

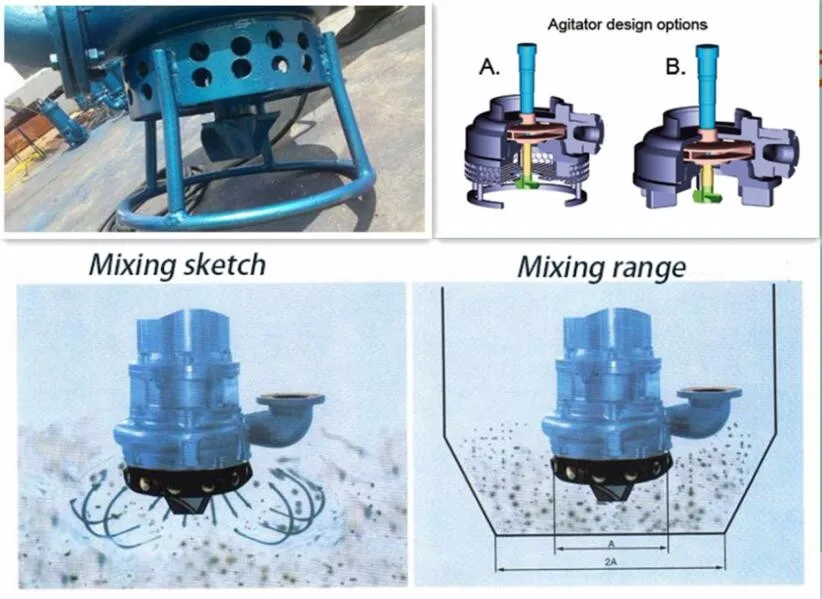

2. Submersible sludge pumps motor and the pump of which are coaxially submerged in medium to work. The overflowing parts of the pump are made from high alloy wear-resistant material, has good wear resistance and large flowing passage.

3. Besides the main impeller, the bottom of the pump is additionally provided with a set of agitation impeller which can spray the deposited sludge into turbulent flow, and therefore the pump realizes high-concentration conveying under the condition of no auxiliary device.

4.The unique seal device can effectively balance the pressure inside and outside the oil chamber, so as to project the reliability of the mechanical seal to the maximum extent.

5.The motor adopts various protective such as overheat protection, water inlet detecting projection, with float switch to control it and can operate safely for a long term in harsh working conditions.

Working Conditions

1. The power source is 50Hz/380V three –phase alternating-current supply, and the capacity of the substation transformator two to three times of the rated capacity of the motor.(If the voltage have special requirements, please inform in advance)

2.The temperature of the medium cannot exceed 60°C, and it does not contain inflammable or explosive gases.

3.The maximum weight concentration of the ash is 45% and maximum weight concentration of the slag is 60%.

4.Maximum submerged depth under the water is 20 meters, the minimum submerged depth takes submerging of the motor as reference.

5.Working status in the medium is vertically and continuous.

Application

This Series of Pumps are used conveying abrasive or corrosive slurry

*Bardge,flue gas desulphurization, metallurgy, mineral processing, mining tailings, coal washing, coal ash, paper and pulp, ball mill, filter press, carbon slurry handling,steel plant, kerosene and crude oil and asphalt and oil residue transporting,ore dressing, building materials, chemical industry and other industrial waste

*Dredging and transferring sand slurry gravel soil sludge mud paste mire slime slush at river, river mouth and sea floor

*Transferring sand, slurry, gravel, soil, sludge at mine, civil works, construction sites, ready mixed concrete factory, Rock Wool Industrial ,Copper Mine Industrail, Petroleum Industrail, chemicals, medicals, medicine company, food industrials, recruiting construction materials factory and clinker of power plant in electric power etc.

*Removal sediment from sumps or basins.

* Mynicipal engineering and construction projects*The water plant sewage discharge water and conservancy project

*Urban sewage treatment plant emissions system

* Farms septic tank

*Tailings convey

Installation

Packaging

1. All of our pumps are packed by the standards plywood box complied with the exportation requirement;

2. We can also customizing the package to pack centrifugal slurry pump according to customer's request;

We have desinged the top-grade quality pump and keep upgrade our product all the time by our professional Engineers Team, we also cooperate with many scientific research institutions and universities to ensure the new products researchment.